Your Medicine, Made Just for You: The future of 3D Printed Drugs.

- ACS BCP

- 6 days ago

- 5 min read

Think of a day when your medicine is not a bland tablet but rather something which

can be printed within no time since you have the to the pharmacy. In the world of

today, this is indeed possible. It is called 3D printing of medicines and it may change

the very way we produce and use drugs. To appreciate the implications of this

technology, pharmacy students note that it integrates the pharmaceutical sciences,

engineering, and innovation in healthcare. And so, we will tackle it ‘science fiction’

on, what is the 3D Printing of Medicines To the uninitiated, 3D printing, the same as

additive manufacturing, is the process where a designer adds layers, within a

framework, to complete the outline of an object. In the pharmaceutical field, the

‘printing’ that is done is not the traditional paper and plastic or metal. Rather, it is the

use of medicines that contain the active drug, printed in the forms of special powders,

liquids, or gels.

The incredible perks of pills you can print-

● Tailored doses for every patient: Traditional tablets are of fixed doses for

example 250 mg or 500 mg. In some cases. Patient will require the same

amount. With 3D printing, doctors may now issue a precise dose of that which

is needed. Many of which, in particular those that have chronic conditions go

on to take many pills a day. 3D printing can produce a single tablet containing

various drugs which in turn reduces the number of pills a patient has to take

and also makes it easier to follow treatment.

● Super-Fast Dissolving Tablets: Some 3D printed drugs (eg- Spritam, which

was the first FDA approved drug) has very fast dissolution rate. It is designed

to disintegrate rapidly in small amount of liquid making it easier for patients.

● Development of Advanced Bioprinting for Tissues and Organs: It is one of

the most revolutionary application, Bioprinting is a process that uses bioinks to

create living tissue structure. It uses patients cells to create functional tissues

for drug testing and disease modelling. This accelerates the pharmaceutical

research by reducing the time of animal testing.

A Real-Life Breakthrough: The Spritam Story

The most renowned 3D printed drug is Spritam containing Levetiracetam , an epilepsy

medication endorsed by the US FDA in 2015. This exceptional formulation technique

enabled only a single unit dose to dissolve instantaneously on water intake for super

fast quick disintegration ensuring as compared to conventional tablets. Thus, it was

verified that 3D printing could offer safer and more effective dosage forms.

The Science Behind the Magic: How It Works

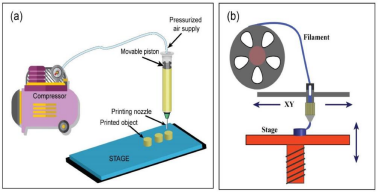

● Extrusion-Based 3D Printing:

This is what we see as the primary method in drug delivery which is of the extrusion

process of a material which is either a paste or a melted filament to create layers. We

have Pressure Assisted Microsyringe (PAM) and Fused Deposition Modelling (FDM)

as the two main types. PAM which uses a semi solid paste it extrudes with pressure. It

does well with heat sensitive materials although it has low resolution which in turn

may require the use of organic solvents. FDM on the other hand uses a solid filament

which is melted and extruded through a heated nozzle. It does away with the use of

organic solvents and puts out very durable products but the high temperatures used

may cause degradation of heat sensitive APIs.

● Inkjet-Based 3D Printing:

It is like old paper printers, inkjet-based 3D printers build 3D objects by depositing

material droplets, each consisting of a portion of the final 3D object. It is subdivided

into continuous inkjet (CIJ) and drop-on-demand (DOD) processes. DOD is the most

favourable in the pharmaceutical industry, especially using piezoelectric print heads,

because it works at room temperature and therefore does not degrade active

ingredients. Further, it is classified as drop-on-liquid, wherein microstructures with

high drug loading ratios are formed, and drop-on-solid, wherein a liquid binder is

jetted onto a powder bed. The latter was used for the first FDA-approved 3D printed

drug, Spritam®. One of the major drawbacks is that the final products are often brittle,

friable, and porous.

● Laser-Based 3D Printing:

It uses a high energy laser to solidify liquid or powder materials. Two methods are

Stereolithography (SLA) which uses a UV laser to cure photosensitive liquid resins

and Selective Laser Sintering (SLS) that uses laser which fuses powdered material in a

single step, solvent free process. However the high thermal requirement in this process

may degrade the Active Pharmaceutical Ingredient (API). SLA reports very high

resolution results although it is a issue of finding FDA approved resins and also of

toxic left over chemicals. Both of these methods have restricted material compatibility

and also high price point of the equipment.

Challenges and Limitations-

3D printing of medicines is interesting, but it still meets some challenges like

● Reach Regulatory Approval: Any 3D printed medication is subject to

approval by regulatory bodies like the FDA and EMA for safety and

effectiveness. It also has to undergo rigorous Microbiological and Bulk

Powder Testing of Active Pharmaceutical Ingredients.

● Marketing and Distribution: The high costs with marketing and distribution

of the 3D printers, along with pharmaceutical grade materials, cloud the

business prospects of mass-sale printer suppliers.

● Volume Production: The ability to construct a single pill is relatively simple,

however, to scale it to millions in a short duration is extremely complex.

● Consistency: The printed pills must follow the pre exemplified prescription,

for any deviation would cause pill imbalance which can pose a significant

threat.

What's Next? A Peek into the Future of 3D-Printed Medicine

● On-Demand Pill Printing at Your Pharmacy: Imagine a pharmacy where a

patient’s customized pill could be printed and ready while they wait in

pharmacy on-demand pill printing!

● Polypills for Simplified Health Management: For the millions of people who

manage chronic conditions like diabetes or high blood pressure, taking multiple

pills daily is a fact of life. The future could bring "polypills" that are single

tablets containing all the necessary medications. This would simplify daily

routines, making it easier to manage health and stick to treatment plans.

Conclusion

The fact that 3D printing of medicines is not merely a new technology but rather a

stride towards advanced personalized medicine makes it all the more interesting. The

prospective pharmacy graduates have the added advantage of observing the pragmatic

integration of pharmacy practice with technology. Very soon, the scope of your

pharmacy practice will no longer be limited to dispensing medicines. You will be able

to actively contribute to the designing and printing of medicines tailored to the

specific requirements of patients.

References-

Comments